S5 Snake Robot Prototype (1998-99)

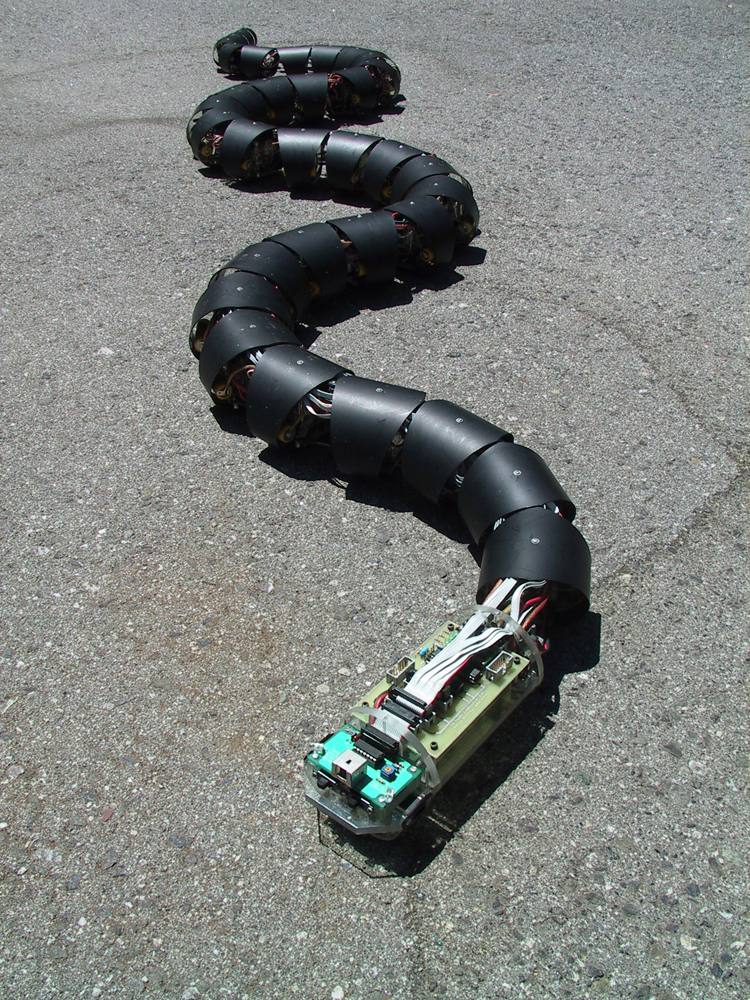

Materials: Polycarbonate plastic, brass rod, and vinyl cladding

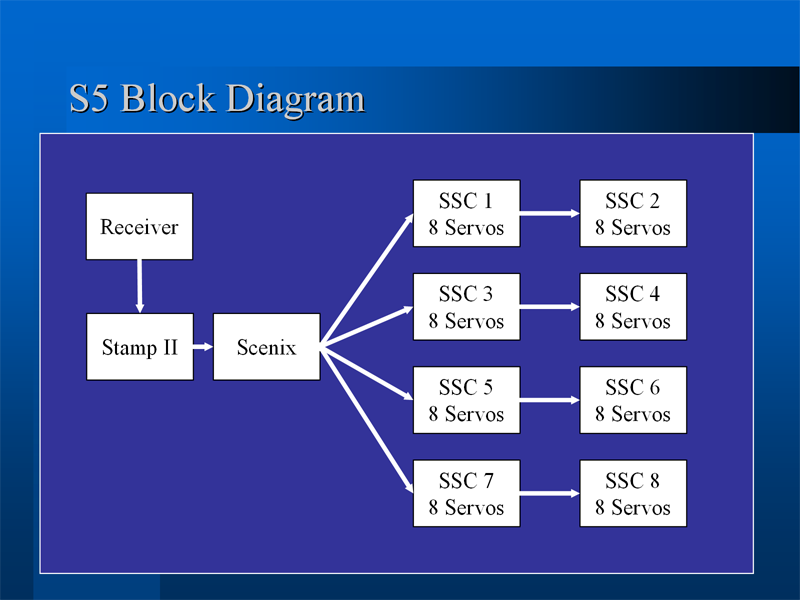

Components: One Basic Stamp II microprocessor (20 MHz), One Scenix Microprocessor (50 MHz), 64 servos, 8 servo control units, 42 batteries, 4 channel radio control.

S5 represents a refinement of the S3 design. Parts were created using a numerically controlled milling machine. This allowed for much more accuracy, and a smaller cross-section.

Almost doubling the number of segments allowed a robot that begins to resemble the length-to-width ratio of chubby real snakes. As the snake grows in size, the design starts to place

heavier requirements on the wiring and control capability. The Basic Stamp controller drives a second, faster processor that supports 4 simultaneous serial buses along the length of the

snake. Segmented cladding was used to give a more continuous look to the overall shape.

S5 electronics functional diagram

© 2002, Gavin Miller.

S5 approaching the camera

© 1999, Gavin Miller.